The Clear View: Understanding Heat Loss and Glazing Technical Specifications:

Windows are essential for light and views, but they can be a major weak point in a building’s thermal envelope,allowing precious heat to escape in winter and unwanted heat to pour in during summer. Understanding how heat loss works and the technical specifications of modern glazing is key to creating a comfortable, energy-efficient space.

This blog post breaks down the science of heat transfer and compares the technical merits of single, double, and triple glazing.

Understanding Heat Loss and Heat Transfer

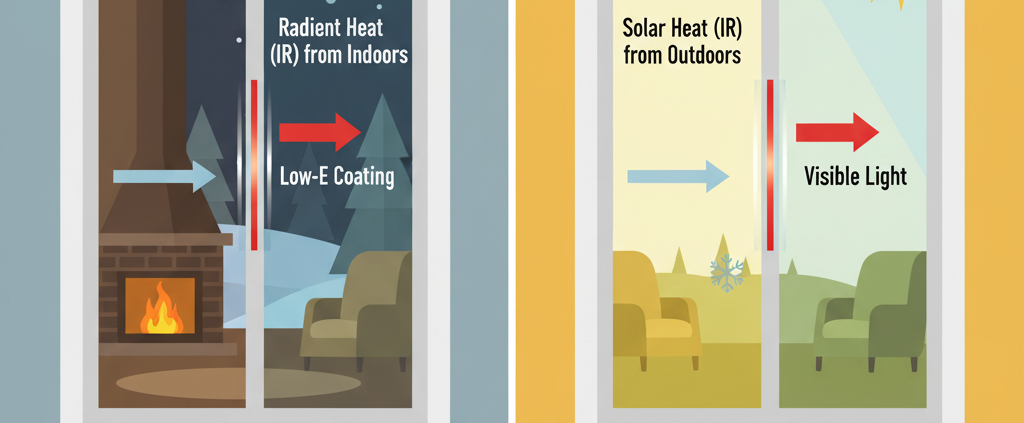

Heat always moves from a warmer area to a cooler area—it’s a fundamental law of physics. Through a window, this transfer occurs in three primary ways:

1. Conduction

- What it is: The transfer of heat through direct contact within a material. In a window, heat from your warm interior air hits the glass, and the thermal energy vibrates through the glass pane itself to the cooler exterior surface.

- Glazing Factor: Glass is a decent conductor, meaning it easily passes heat. In single glazing, conduction is a major heat loss pathway.

2. Convection

- What it is: The transfer of heat through the movement of fluids (like air or gas). Warm air next to the inside pane of glass rises, is cooled by the glass, and then falls, creating a circulating current that draws heat from the room and delivers it to the cold inner pane.

- Glazing Factor: This is where the gap in multi-pane glazing comes in. The sealed space between panes prevents large-scale air movement, significantly reducing heat transfer by convection.

3. Radiation

- What it is: The transfer of heat via electromagnetic waves, particularly in the infrared spectrum. Everything warm radiates heat. Your interior walls, furniture, and body radiate heat, and a portion of this energy passes directly through the glass to the outside.

- Glazing Factor: This is often the largest source of heat loss in a standard window. Modern innovations like Low-Emissivity (Low-E) coatings are designed to address this by reflecting the long-wave infrared heat back into the room while still allowing visible light to pass through.

Here’s an illustration of these heat transfer methods:

The Key Technical Metric: The U-Value

To quantify a window’s thermal performance, we use the U-value (also known as the coefficient of heat transmission).

- What it is: The rate of heat loss through a structure (like a window) per unit area for every degree of temperature difference between the inside and outside.

- Unit: Watts per square meter Kelvin ().

- The Goal: A lower U-value means better insulation and less heat loss, leading to greater energy efficiency and lower heating bills.

Glazing Technical Specifications Compared

The number of glass panes and the contents of the gap between them fundamentally change a window’s U-value and overall efficiency.

Here’s a visual comparison of single, double, and triple glazing:

Key Technical Enhancements in Modern Glazing:

- Insulating Gas Fills: Argon vs. KryptonReplacing the air in the sealed cavity with an inert gas significantly improves thermal performance, primarily by reducing convective and conductive heat transfer.

- Argon Gas:

- Properties: Argon is a non-toxic, odorless, clear, inert gas that is denser than air. It’s relatively inexpensive and readily available.

- Performance: Due to its higher density and lower thermal conductivity compared to air, Argon slows down the movement of heat within the window’s cavity. This dramatically reduces convection currents and conduction.

- Application: It’s the most common gas fill for both double and triple glazed units, especially in standard cavity widths (typically 12mm-16mm).

- Krypton Gas:

- Properties: Krypton is also an inert, non-toxic, clear, odorless gas, but it is much denser than Argon and significantly more expensive.

- Performance: Its superior density and even lower thermal conductivity make it an even better insulator than Argon.

- Application: Krypton is particularly effective in smaller cavity widths (e.g., 6mm-10mm), where Argon’s effectiveness might be limited due to its molecular size. This makes it ideal for triple glazed units where space between panes might be tighter or for achieving extremely low U-values in compact designs.

- Cost vs. Benefit: While more expensive, Krypton allows for thinner, lighter, and sometimes more aesthetically pleasing window units that still achieve superior thermal performance. It’s often used in high-performance windows, passive house designs, or when specific U-value targets must be met in limited space.

In essence, the denser the gas, the slower heat can move through it, leading to better insulation.

- Argon Gas:

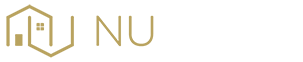

- Low-Emissivity (Low-E) Coatings: A Deeper DiveLow-E coatings are the unsung heroes of modern window technology, specifically tackling radiant heat transfer.

- What it is: An incredibly thin, virtually invisible metallic oxide layer applied to one or more glass surfaces within the insulated glass unit (IGU).

- How it Works (The Science):

- Emissivity: All materials absorb and radiate heat. Emissivity is a measure of how well a material radiates energy. Standard clear glass has high emissivity, meaning it readily radiates absorbed heat.Low-E coatings, as their name suggests, have low emissivity.

- Reflection vs. Absorption: Low-E coatings are designed to reflect long-wave infrared (IR) radiation (heat) while allowing most visible light to pass through.

- In Winter: The coating reflects internal heat back into the room, preventing it from escaping outside.

- In Summer: The coating reflects external heat (from the sun’s warm rays) away from the building, preventing it from entering and overheating the space.

- Types of Low-E Coatings:

- Hard Coat (Pyrolytic): Applied during the manufacturing process of the glass (on-line), fusing a thin metallic oxide layer to the glass. It’s very durable but generally has slightly higher emissivity (meaning it’s slightly less efficient) than soft coats.

- Soft Coat (Sputtered): Applied in an off-line process in a vacuum chamber. These coatings are typically multi-layered and provide superior performance (lower emissivity). However, they are more delicate and must be protected within the sealed unit. Most high-performance windows use soft-coat Low-E.

- Placement Matters: The specific surface within the IGU where the Low-E coating is applied depends on the climate and desired performance (e.g., passive solar gain vs. solar control). Common placements include surface #2 (facing the cavity from the inside pane) or surface #3 (facing the cavity from the outside pane of a double-glazed unit).

Here’s an illustration showing how Low-E coatings work:

- Warm Edge Spacers: The material separating the glass panes around the edge. Using materials like foam or composite instead of highly conductive aluminum minimizes heat loss at the perimeter of the unit. This improves the overall U-value and reduces the risk of condensation forming at the edge of the glass.

Making the Right Glazing Choice

Choosing your glazing is a balance of performance, cost, and climate.

- For the Majority of Homes (Standard UK/Temperate Climate): Modern Double Glazing with Low-E coating and Argon gas offers the best balance of cost and performance. The jump in efficiency from single to double glazing is monumental.

- For Extreme Cold or Passive House Builds: Triple Glazing provides superior thermal performance, achieving a U-value that often rivals an insulated wall. The increased initial cost is offset by maximum long-term energy savings.

- Single Glazing: Now considered obsolete for habitable rooms due to its catastrophic heat loss. It rarely meets modern building regulations.

In conclusion, the days of relying on a single sheet of glass are long over. By understanding the three mechanisms of heat transfer and specifying a low U-value using multi-pane units, inert gas fills (Argon for most, Krypton for high-performance in tight spaces), and Low-E coatings, you can transform your windows from energy liabilities into energy-saving assets.

Leave a Reply

Want to join the discussion?Feel free to contribute!